In daily life, have you ever encountered these situations?

When the mobile phone is placed next to the computer, the WiFi signal suddenly becomes weak?

When the electric bike is charging, there is noise in the radio?

The "culprit" of these phenomena may be the failure to meet EMC (Electromagnetic Compatibility) requirements!

Simply put, EMC (Electromagnetic Compatibility) is the ability to make different electronic devices "coexist peacefully" in the same space. It contains two basic requirements:

01 Do not interfere with others (EMI)

02 Not be interfered by others (EMS)

We can imagine EMC (Electromagnetic Compatibility) as a traffic rule: All vehicles (electronic equipment) must abide by the traffic lights (standard limit values), cannot honk randomly (generate interference), and at the same time, must have a good braking system (anti - interference ability) to avoid accidents caused by other vehicles suddenly changing lanes.

Three Elements of EMC (Electromagnetic Compatibility) Issues

Every EMC (Electromagnetic Compatibility) issue is like a "love triangle" drama, requiring three roles to perform together:

01 Interference Source

02 Propagation Path

03 Sensitive Equipment

"Victims" affected by interference, such as radios, medical equipment, automotive electronic systems, etc.

Why is EMC Important?

EMC (Electromagnetic Compatibility), although a specialized field, directly impacts a product’s performance, reliability, and time - to - market. As regulations in various countries become increasingly stringent, proactively planning for EMC will be the key to a product’s success.

There are three fundamental techniques for solving EMC problems:

02 Grounding

03 Filtering

What Can We (Vookey New Material) Do?

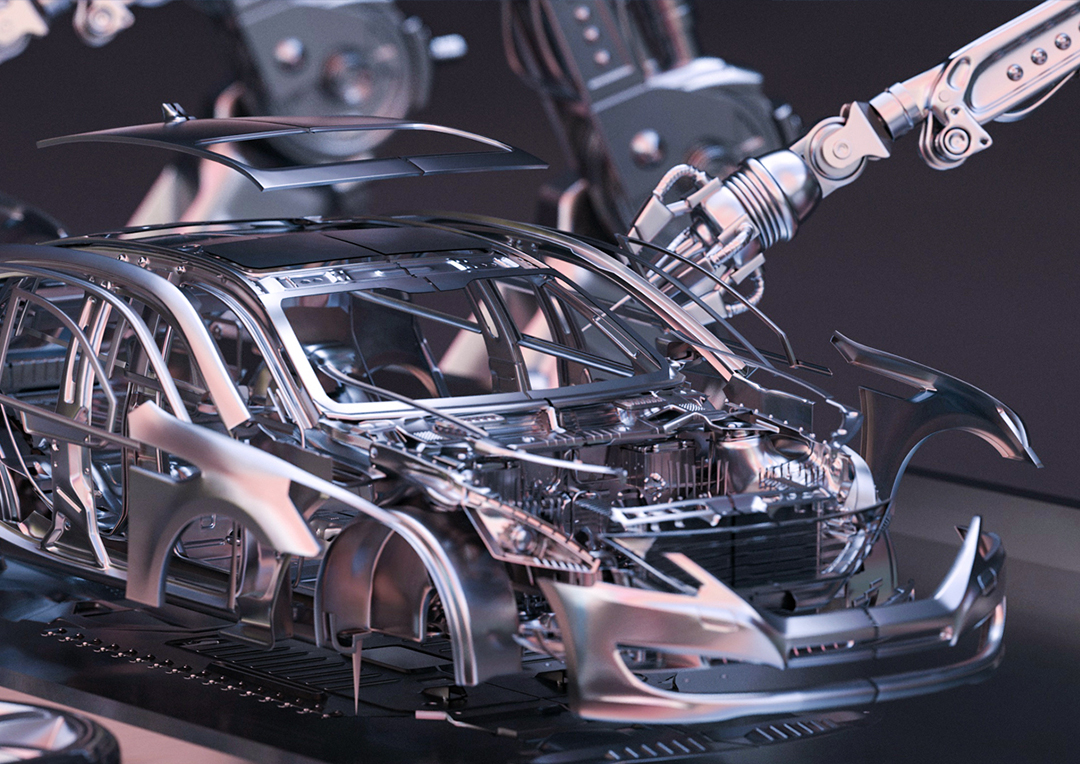

In the field of EMC materials and solutions, Vookey New Material (Shanghai) Co., Ltd., leveraging years of global project application experience, has become a pacesetter in the industry. As a company that has focused on electromagnetic shielding design, sealing design, thermal design, etc. for automotive and communication products for many years, it can provide customers with one - stop solutions for complex engineering needs. From the product concept design stage to the mass production stage, it fully supports customers' engineering teams, covering application fields such as electromagnetic shielding materials, sealing materials, thermal materials, and wave - absorbing materials for automotive and communication products. Meanwhile, it provides solutions for automotive windshield wipers and shaft current conduction rings.

The core competitiveness of Vookey New Material is reflected in:

02 Quality Assurance

03 Application Experience

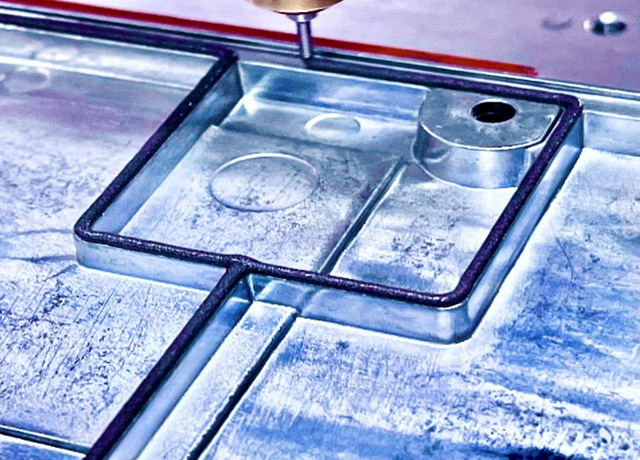

Vookey EMC Star Product——Conshield VK8101 Conductive Adhesive:

EMC Guardian for Precision Electronic DevicesConductive adhesive, as a functional adhesive, is increasingly widely used in the electronics industry. It can not only provide stable electrical conductivity but also achieve adhesiveness and sealing properties, making it an ideal choice to replace traditional welding and mechanical fixing. Our conductive adhesive products cover various material series such as nickel - carbon and silver - copper. The electrical conductivity and mechanical properties can be adjusted according to different application requirements.

For example: The Conshield 810X series of nickel - carbon conductive adhesives focus more on corrosion resistance and environmental adaptability, suitable for automotive electronics and outdoor equipment; The Conshield AIR series of silver - copper conductive adhesives are suitable for high - frequency signal shielding, featuring low resistance and high reflection characteristics; Two - component high - temperature curing conductive adhesives can meet the requirements of high - reliability packaging, such as in the aerospace and special fields. Whether it is for the fixing of flexible circuit boards or the shielding and packaging of sensor modules, our conductive adhesives can provide stable and long - lasting performance.

01 High - temperature Resistance

02 Salt Spray Resistance

03 Waterproof and Shock - proof

04 Lightweight

Compared with metal shielding covers, the weight is reduced by more than 50%.

In applications such as 4D millimeter - wave radars, intelligent seats, and battery management systems (BMS), our EMC shielding materials can effectively suppress electromagnetic interference, ensure the precision of signal transmission, and contribute to the development of intelligent driving technology.

In an era where electronic devices are increasingly dense, let Vookey join hands with you to jointly create a more compatible and reliable intelligent future!